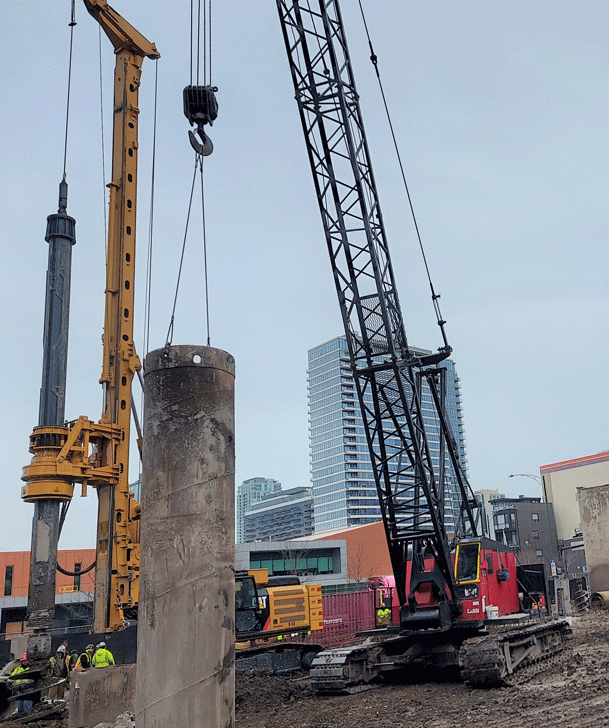

Caissons are formed by excavating cylindrical shafts into the ground and filling them with reinforced concrete. What differentiates caissons from other drilled foundations is the drilling technique using a short auger that is advanced with high torque and downward force (crowd) from a telescoping kelly bar. The auger is filled and emptied many times to create a shaft. By drilling in this fashion, very large diameters and high capacities can be achieved.

Caissons are drilled to a suitable bearing layer as determined by the geotechnical engineer and may have to extend to bedrock. When bearing on soil, caissons are often “belled” at the base to increase the bearing area.

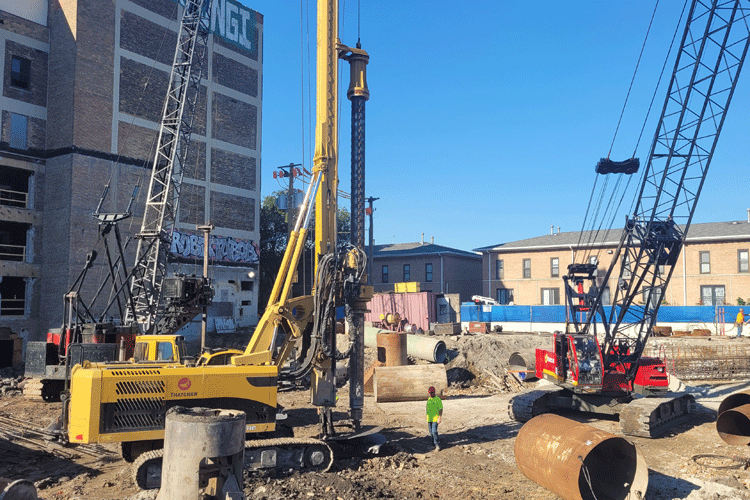

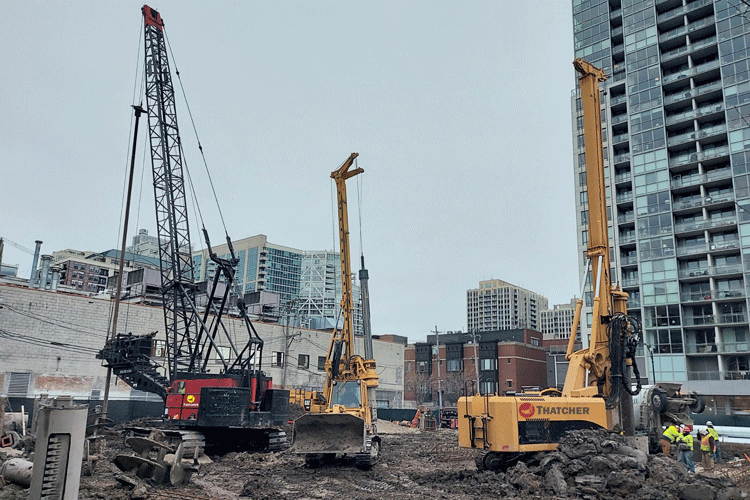

Thatcher’s caisson work is directed by Jay Luther, who spent over 30 years with Revcon Construction Corporation. Revcon was a well-respected local firm that specialized in belled caissons from 1984 to 2021. The Thatcher team has been joined by several other former Revcon employees who know how to safely install high quality deep foundations, with industry leading efficiency.

Thatcher Foundations has been the clear leader in pile driving in Chicago for decades. We have driven piles for everything from private residences and local businesses, to some of Chicago’s largest buildings. From over 52,000 timber piles driven for the Jardine Water Purification Plant in 1964 to over 2,200 H-piles for the new Soldier Field in 2002, Thatcher Foundations has been the contractor to get the tough, big jobs done right and on schedule.

We specialize in driven piles because they are the most reliable form of deep foundation system. Every pile is driven with a known amount of energy until it reaches a specific driving resistance. This offers an inherent level of quality control beyond all other types of deep foundation installation techniques. A DRIVEN PILE IS A TESTED PILE

Micropiles are small diameter, typically less than 12 inches, piles that are drilled using small rigs. The piles are named for the size of the rigs, not the capacity of the piles. Common working loads are 40 to 200 kips, but Thatcher has installed the highest capacity micropiles in Chicago with a working load of 600 kips, ie, tested ultimate capacity exceeding 1200 kips!

Micropiles are high strength steel pipes usually socketed into rock. They are primarily used for underpinning existing structures. Thatcher has a range of micropile rigs that range in size from very small that can get through a man door to larger, more productive rigs where access is not as restricted.

Augercast piles, also known as continuous flight auger (CFA) piles or auger grouted piles, are cast-in-place piles using a hollow stem auger with a continuous flight. The term CFA pile is often used to describe the same type of pile but with a fixed mast rig instead of a crane suspended set up.

Augercast piles are installed by rotating the auger all the way to the bearing depth in one stroke. Concrete or grout is pumped through the hollow stem to fill the void created as the auger is withdrawn. The grout pressure and volume must be carefully controlled to construct a continuous pile without defects. The reinforcement steel is then inserted in the fresh pile. There is usually a full-length bar and often a cage in the upper portion.

Augercast piles are typically 12 to 24 inches in diameter with design loads from 40 to 400 kips. Thatcher has installed augercast piles in Chicago tested to an ultimate capacity of 2,640 kips. Augercast piles have been installed in low headroom, but micropiles are better suited and higher quality solutions for these applications.

Drilled Displacement piles are similar to augercast piles but installed without significant soil removal and instead displace the soil laterally. They thereby improve the soil by increasing lateral pressure, and in granular soils can densify them. These piles take considerably more torque and crowd to install. A partial displacement pile is in between a CFA and full displacement pile. A partial displacement pile allows a small amount of soil to be conveyed upward from the tip, with the amount of displacement dependent on the skill/technique of the contractor.

There are many names used for drilled deep foundations in the industry. The same element can be called different names depending on local practice. Chicago uses the term “Caisson” for shafts drilled with a kelly bar while the rest of North America uses the term “Drilled Shaft,” and in Europe they prefer “Bored Pile.” The term “CFA Pile” refers to those constructed with a continuous flight auger, similar to augercast piles, however its commonly reserved for those with larger diameters drilled with fixed mast rigs. Drilled piers can be installed many ways, but typically the term refers to foundation elements with sufficient diameter to stand alone under a column (e.g. at least 30 inches in Chicago). Thatcher provides design build services to provide the optimum solution for any geotechnical and loading conditions. With the arrival of Jay Luther and others from Revcon, Thatcher can provide any solution to meet jobsite demands.

Jacked piles and piers are typically small diameter steel pipes installed to bearing depth by hydraulic jacks. Jacked piles are a method of underpinning existing structures by attaching to the structure and using its dead weight for reaction to create downward force. The load necessary to install the pile is measured, so the exact capacity of every pile is known. It is also vibrationless.

Helical piers, also known as helical piles or screw piles are usually small diameter pipes or tubes with a single or a few helices near the tip of the shaft. They are typically used in groups like piles and do not stand alone as would a pier, but the helical pier terminology is commonly used. Helicals were originally developed as low capacity anchors in the electrical industry. They can be used as compression elements as well, typically for lighter structures. Compression loads should not be applied on anything less than 3 inch diameter. Looseness in the connections can be an additive problem and therefore requires attention to detail. Larger helical piles have also been used.