Thatcher has developed techniques and equipment for solving challenging problems that can be applied to different types of deep foundations or support of excavation. The harder the problem, the more creative and valuable we become. Some of our most useful help is figuring out ways to avoid using us. That legacy has served Thatcher well through the years of mostly repeat business.

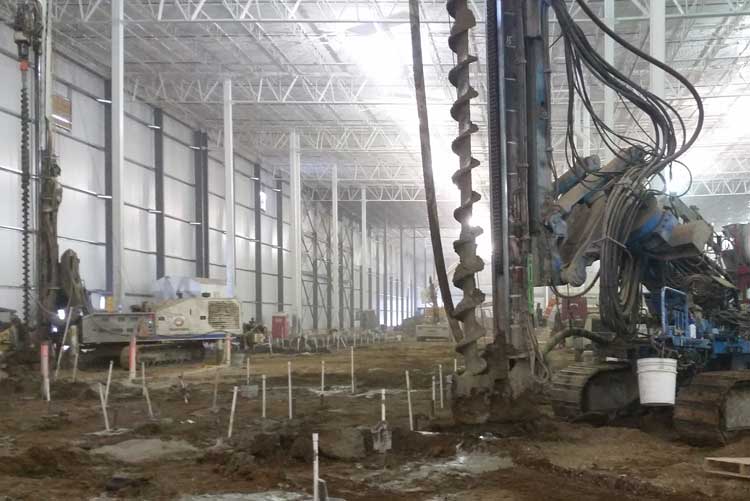

Thatcher has been working in limited access situations for many years and has several approaches to meet the jobsite conditions. We have a wide range of equipment to use all the headroom that is available in order optimize the technique. We have done a lot of work in the industrial sector in limited headroom in the 25 to 50’ range using small versions of big machines, or big versions of small machines. We have tools to get all the way down to pass through a man door.

Thatcher has been working with grout in various forms since the 1970’s. The primary purpose has been as part of a structural support element. This includes augercast piles with fine aggregate grout from concrete suppliers and micropiles/soil anchors with neat cement grout and post grouting that is mixed on site.

Water cutoffs and soil structural stabilization are also done as part of earth retention systems. Grout is often used to treat leaks in slurry walls, secant walls, or sheet pile interlocks. These are usually chemical grouts, microfine cement, or specially developed mineral grouts that are adjusted for the given application.

Thatcher has performed ground stabilization with compaction grouting, soil mixing, permeation grouting, and void filling. We have a wide array of techniques available to meet a given job requirement. We have developed our own grouts through thorough prejob testing to meet environmental requirements. We have a wide range of tools from colloidal mixers to various pumping systems available.

Vibrationless piling refers here to hydraulically pressed steel sheet piling. The same installation technique for deep foundations is more commonly called jacked piles. Thatcher has led the industry in vibrationless piling techniques since the 1980’s. Tom Wysockey went to Japan to observe sheet pile pressing devices in action. Thatcher used what was then called the “Still Worker” to install both sheet piles and H Piles.

Current techniques are far more cost and time competitive, but several of the lessons learned are still valuable today. The most common challenge is penetrating harder or denser soils, which can make the technique not viable in certain situations.

Ground improvement often refers more to an analysis technique than a new type of foundation element. Any pile can be used for ground improvement. The fundamental difference is that ground improvement piles work by carrying a portion of the load, while the surrounding soil carries the rest. Traditional piles will carry 100% of the load. Many years ago, we installed timber piles designed by Clyde Baker as “settlement reducers” using this same concept. When ground improvement piles are displacement piles (driven or drilled), they will improve the surrounding soil matrix, primarily by densifying granular material.